ISO 9001:2015 Clauses 6.2 & 6.3 – Quality Objectives and Planning for Change in Your QMS

Introduction

Establish meaningful goals for your business with ISO 9001:2015. Dive into Clauses 6.2 and 6.3 to learn how to set measurable quality objectives and manage changes effectively. Discover how strategic planning ensures your QMS drives both customer satisfaction and organizational success. These clauses encourage organizations to translate their vision into actionable, trackable outcomes while ensuring smooth adaptation to changes without compromising quality. With Maxicert’s ISO certification expertise, businesses can confidently align their objectives with long-term strategies and implement structured change management processes that strengthen performance and resilience.

6.2 Quality Objectives and Planning to Achieve Them

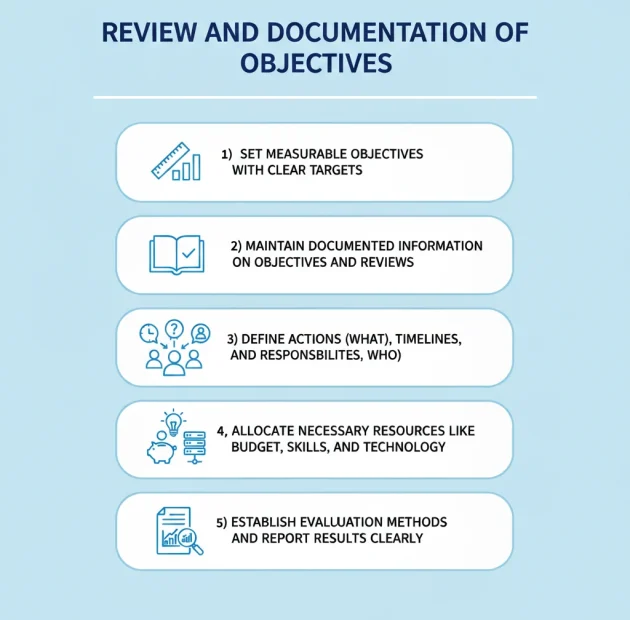

Quality objectives are clear and measurable goals set by an organization to improve product and service quality. They align with the quality policy and help meet customer needs. The organization plans what actions are needed, who is responsible, and when to complete them. These objectives are regularly monitored, communicated, and updated to ensure continuous improvement.

6.2.1 The organization shall establish

Quality objectives at relevant functions, levels and processes needed for the quality management system. The quality objectives shall:

- Be consistent with the quality policy;

- Be measurable

- Take into account applicable requirements

- Be relevant to conformity of products and services and to enhancement of customer satisfaction

- Be monitored

- Be communicated

- Be updated as appropriate.

The organization shall maintain documented information on the quality objectives.

6.2.2 When planning how to achieve its quality objectives, the organization shall determine:

- what will be done,

- what resources will be required;

- who will be responsible,

- when it will be completed;

- how the results will be evaluated.

By following the requirements in 4.3, 4.4 the scope and processes of the QMS have been identified and you will have established your quality policy per 5.2. In order to put this policy into effect, top management needs to establish clearly defined objectives that your organization can aim for. This does not need to be carried out personally by top management but the responsibility is still theirs.

It is important that these objectives are not vague but address what’s important to you and your customers.

ISO 9001:2015 Clause Guide Panel

- Clause 1

- Clause 2

- Clause 3

- Clause 4 – Sub-clause 1

- Clause 4 – Sub-clause 2

- Clause 5 – Sub-clause 1

- Clause 5 – Sub-clause 2

- Clause 5 – Sub-clause 3

- Clause 6 – Sub-clause 1

- Clause 6 – Sub-clause 2

- Clause 7 – Sub-clause 1

- Clause 7 – Sub-clause 2

- Clause 7 – Sub-clause 3

- Clause 7 – Sub-clause 4

- Clause 8 – Sub-clause 1

- Clause 8 – Sub-clause 2

- Clause 8 – Sub-clause 3

- Clause 8 – Sub-clause 4

- Clause 8 – Sub-clause 5

- Clause 8 – Sub-clause 6

- Clause 8 – Sub-clause 7

- Clause 8 – Sub-clause 8

- Clause 8 – Sub-clause 9

- Clause 8 – Sub-clause 10

- Clause 8 – Sub-clause 11

- Clause 8 – Sub-clause 12

- Clause 9 – Sub-clause 1

- Clause 9 – Sub-clause 2

- Clause 9 – Sub-clause 3

- Clause 9 – Sub-clause 4

- Clause 10

Basis for Setting Quality Objectives

An organization can develop quality objectives on the basis of the results of the identification and prioritization of risks. Planned risk treatment actions are essentially quality objectives. The development of quality objectives shall be taken into account development directions identified in the quality policy.

The objectives need to be realistic and related to achievable outcomes, such as:

- meeting the requirements (customer, regulatory and other) for products and services,

- meeting the planned schedule,

- identifying opportunities for improvement, and

- identifying new market opportunities.

Relevance Across the Organization

This clause also requires that relevant objectives (e.g., process performance, continual improvement) are established at appropriate parts of your organization (e.g., human resources, production, sales). It is important that you and your people are aware of how they contribute to the achievement of the quality objectives.

The organisation may have an objective of 100% on-time delivery. However, in order to meet that objective it might have to set a more specific objective relating to meeting daily planned schedule requirements. This, in turn, might generate an even more localized objective of decreasing turnaround time for fitting all components for an assembly job.

Measurable Quality Objectives

Quality objectives need to be measurable. They should be based on analysis of the current status of a product or process, with the intent of improving the outcome in a manner that can be measured.

At the service delivery/customer interface or at the production line, objectives can be very simple and direct, as shown by these examples:

- A transport organization running a bus service might set an objective for the percentage of buses that will run to the scheduled timetable within set limits.

- At a production location, the objective output per hour with maximum acceptable reject level can be set.

- In a hairdressing salon, for the times when all available staff are busy, one person can be assigned to greet new customers. The objective here might be that “customers entering the shop are to be welcomed within one minute and their requirements ascertained”.

At higher levels in the organization, objectives can get more complex.

For example, in the case of the hairdressing salon, the owner/manager could set a further objective of having sufficient staff available to meet peak demand times. This might require planning, employing temporary staff, training them, and so forth.

Review and Documentation of Objectives

6.3 Planning of Changes

When the organization determines the need for changes to the quality management system, the changes shall be carried out in a planned manner (see 4.4). The organization shall consider:

a) the purpose of the changes and their potential consequences;

b) the integrity of the quality management system;

c) the availability of resources;

d) the allocation or reallocation of responsibilities and authorities.

Key Focus in Managing Change

A key focus in dealing with any change is to minimise the impact on conformity of product and services to requirements and to ensure the integrity of the QMS. Changes can occur in a number of ways.

Identification of the Need for Change

The identification of the need for a change can occur in any number of ways. The need for change may come from:

- external sources (e.g., changes to product or service based on customer feedback, supplier of new material, new IT system for customer interface), or

- internal sources (e.g., identified problems with processes or products or changes as part of an internal improvement initiative, see 10).

Reactive Changes

When things go wrong with the delivery of a service or a product or with the processes of the QMS there may also be a need for a change i.e. a reactive change. It may be too late to prevent the provision of the service or the delivery of the products but the issue should be identified and analysed to determine what changes are needed to prevent reoccurrence or what action is needed to mitigate the problem — see 8.5.6., 8.7 & 10.2.

Importance of Analysis and Trending

Analysis and trending of results and data is important in determining possible changes, which should be planned.

Planning Changes Properly

All changes should be planned and assess the changes and the possible impacts on the QMS.

When planning changes to the quality management system the organization should address the risks (see Clause 6.1) associated with these changes on the issues outlined in this section of the standard from a) to d).

Conclusion

Clauses 6.2 and 6.3 of ISO 9001:2015 are intrinsically linked, forming the backbone of strategic QMS management. Clause 6.2 gives your organization a clear direction by requiring measurable, communicated objectives that are aligned with your quality policy. In turn, Clause 6.3 provides the framework to navigate the journey toward those objectives by ensuring that all necessary changes are planned, proactive, and risk-assessed. By treating quality objectives not as mere paperwork but as living goals, and by managing change as a planned, strategic activity, your organization can maintain the integrity of its system, enhance customer satisfaction, and ensure continuous improvement. With Maxicert’s guidance, organizations can turn these requirements into practical actions, ensuring goals are realistic, well-communicated, and adapted to evolving business growth.

Free 60–90 day implementation plan available after consultation.

Client Testimonials

What Our Clients Say About Us?

We are trusted by thousands of clients belonging from technology, manufacturing, healthcare and various sectors

Our overall experience with Maxicert was satisfied. The audit and consulting part was handled carefully, we fulfilled our client requirement of ISO 27001 hassle free.

Kevin Santiago BDM – Clarks Outsourcing, PhilippinesTimely response and knowledge of ISO standards can be seen together in the team of Maxicert, we grow because of the service providers like Maxicert.

Samuel Christopher Quality Assurance Head – OEQA, NigeriaWe did Food safety certification with Maxicert, the service was extraordinary and their consultant had good experience of the subject.

Mr. Venkatesh Production Manager - Acacia Foods and Beverages, ZambiaWe engaged a consultant of Maxicert for our business certification, we now have a well-designed and organized department procedures and we rectify our errors through internal audits regularly.

Abdullah Al Rayes Managing Director – TCS, BahrainTechnical expertise by the team of Maxicert helped us achieving our ISO 13485 certificates, we now proudly say that we have achieved our target, all thanks to the team.

Nady Boustany CEO – LMG, IraqMaxiCert's approach to meet our needs proved instrumental in facilitating a seamless transition throughout the entire ISO certification process for us. Their training sessions are so much helpful.

Ms. Latifa Al Salem Investor portfolio – Ministry of Investment, Saudi ArabiaMaxicert is a one stop solution, we got trainings, documents, audit and certification at one place, they facilitated everything.

Ms. Mariam Chaggama VP – Fasthub, TanzaniaFAQ

What are quality objectives in ISO 9001:2015?

Quality objectives are clear, measurable goals set by the organization to improve its products, services, and customer satisfaction. They help turn the company’s quality policy into real actions everyone can work toward.

How do you make quality objectives effective?

Effective quality objectives should be SMART — Specific, Measurable, Attainable, Relevant, and Time-bound. This means they should be clear, trackable, realistic, important to the business, and have a deadline to achieve them.

Who is responsible for setting and achieving quality objectives?

Top management is responsible for establishing the objectives, but people at different levels and departments should know their roles in reaching them. Assigning clear tasks and resources helps everyone contribute to the goals.

How should organizations plan changes to their QMS?

Any changes to the Quality Management System should be carefully planned by considering the purpose, impact, resources, and responsibilities. Planning helps prevent negative effects on product quality and keeps the system working smoothly.

Their presence in Oman made us even better to accomplish our goal of achieving ISO certificates on time, we will definitely recommend their services.

Mr. Sailesh Mohanakrishnan Division Manager – Khimji Ramdas, Oman