Finalizing Quality: A Guide to ISO 9001:2015 Clause 8.6

Introduction

Ensuring every product and service meets the highest standards is essential for ISO 9001 certification. Clause 8.6 provides a reliable structure for release verification, acting as the final checkpoint before products or services reach the customer. This process, supported by documented evidence, confirms that all requirements defined throughout the quality management system have been met. By meticulously performing this final check, organizations protect their brand reputation and build lasting customer confidence. It’s the critical final step that verifies conformity and mitigates the risk of non-conforming products reaching the market.

For expert assistance in implementing these controls and achieving ISO certification, partner with Maxicert.

8.6 Release of Products and Services

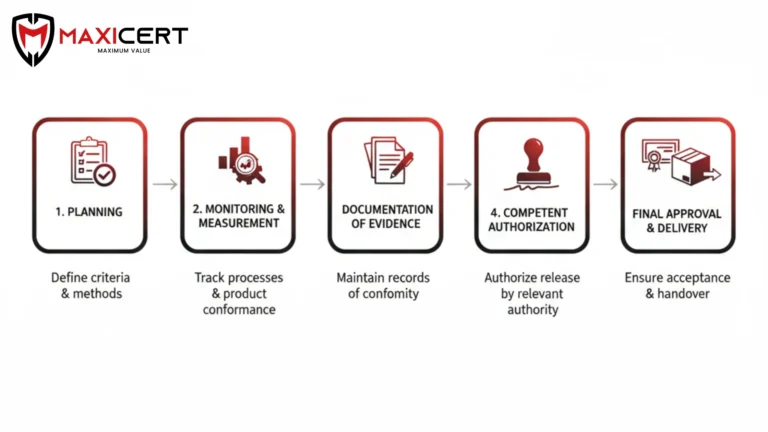

Organizations must plan, document, and perform checks at every relevant stage to confirm product or service requirements are met, in alignment with operational planning.

- Release only after verification, unless specially approved by a relevant authority.

- Prevents nonconformities from reaching the customer, mitigating risks and potential liabilities.

- Strengthens overall quality management system by providing a clear, final gate.

Documented Evidence and Authorization

Maintaining complete records is crucial for quality assurance and compliance, providing a history of the product’s quality journey.

- Evidence of conformity for each release, such as inspection reports, test results, or certificates of conformance.

- Traceability to the authorized individual(s) who approved the release, ensuring accountability.

Supports audits and internal reviews by providing clear, objective evidence of a product’s compliance status.

Monitoring and Measurement Controls

Effective monitoring and measurement reduce the risk of errors and ensure continual quality, serving as the basis for release decisions.

- Create detailed quality plans and sampling procedures, outlining what, when, and how to inspect.

- Define acceptance criteria tailored to each product or service, clearly stating pass/fail conditions.

- Use calibrated tools and updated standards for measurement, guaranteeing the accuracy of all data.

- Establish documented procedures for monitoring and measuring activities, ensuring consistency and repeatability across all operations.

- Retain documented information of the monitoring and measurement results as evidence of conformity and for future reference during audits or trend analysis.

ISO 9001:2015 Clause Guide Panel

- Clause 1

- Clause 2

- Clause 3

- Clause 4 – Sub-clause 1

- Clause 4 – Sub-clause 2

- Clause 5 – Sub-clause 1

- Clause 5 – Sub-clause 2

- Clause 5 – Sub-clause 3

- Clause 6 – Sub-clause 1

- Clause 6 – Sub-clause 2

- Clause 7 – Sub-clause 1

- Clause 7 – Sub-clause 2

- Clause 7 – Sub-clause 3

- Clause 7 – Sub-clause 4

- Clause 8 – Sub-clause 1

- Clause 8 – Sub-clause 2

- Clause 8 – Sub-clause 3

- Clause 8 – Sub-clause 4

- Clause 8 – Sub-clause 5

- Clause 8 – Sub-clause 6

- Clause 8 – Sub-clause 7

- Clause 8 – Sub-clause 8

- Clause 8 – Sub-clause 9

- Clause 8 – Sub-clause 10

- Clause 8 – Sub-clause 11

- Clause 8 – Sub-clause 12

- Clause 9 – Sub-clause 1

- Clause 9 – Sub-clause 2

- Clause 9 – Sub-clause 3

- Clause 9 – Sub-clause 4

- Clause 10

Examples of Monitoring and Measurement

Organizations can use multiple methods to verify product and service quality across various industries.

- Physical measurements (dimensions, color, chemical properties) to confirm product specifications.

- Document proofreading and review in the service industry to verify accuracy of reports or contracts.

- Analysis of process parameters (speed, temperature, time) to confirm stable production conditions.

- Performance monitoring of employees or services against a defined standard.

- Validation of training and software outcomes to ensure they meet their intended purpose.

Competence and Authority

Tasks should only be performed by qualified personnel to ensure accurate release decisions, as their expertise is critical to upholding quality.

- Assign release authority to competent staff who have the necessary knowledge and training.

- Document release responsibilities and approvals, creating clear lines of authority.

- Regularly train employees for updated requirements and procedures to maintain their competence.

ISO 9001:2015 Clause 8.6 Release of Products and Services

Suitable Methods and Documentation

Consistent application of proper documentation supports continual improvement and compliance, turning data into actionable insights.

- Document monitoring and measurement in quality plans and inspection reports.

- Use inspection reports, checklists, and customer order records as formal evidence of release.

- Store release documentation in an organized system for easy traceability and reference during audits.

Final Approval and Delivery

Release procedures must cover all necessary checks before products or services reach the customer, representing the final step in the quality assurance process.

- Verify performance against all defined acceptance criteria from the quality plan.

- Complete all inspections and tests specified for the product or service.

- Prepare and audit accompanying paperwork (e.g., certificates of conformity, delivery notes).

Confirm readiness for customer delivery by ensuring no nonconformities remain.

Conclusion

ISO 9001:2015 Clause 8.6 is a critical final control for ensuring products and services meet quality expectations. By providing structured controls for their release and the necessary documentation, it verifies that all preceding processes have been successful. This ensures the output is certified, traceable, and reliable. Implementing these practices not only drives continuous improvement but also demonstrates a commitment to quality assurance, which builds lasting trust and confidence with customers and partners.

For expert guidance on implementing these controls and achieving ISO certification, partner with Maxicert.

Free 60–90 day implementation plan available after consultation.

FAQ

Why is documented evidence crucial for the release of products and services?

Documented evidence provides objective proof that all product or service requirements have been met before release. It is essential for traceability, ensuring accountability, and supporting audits by providing a clear history of a product’s compliance status.

When is it permissible to release a product or service without full verification?

A product can only be released without full verification if it is done under special approval from a relevant authority, such as the customer. All such approvals must be properly documented to maintain compliance with the standard.

What role does competence play in the product release process?

Competence is critical because it ensures that all release decisions are made by qualified personnel with the necessary knowledge and training. Organizations must assign this authority to competent staff and keep records of who approved each release.

How does an organization verify the release of a service compared to a physical product?

For a physical product, verification might involve physical measurements, tests, or final inspections. For a service, it could include proofreading documents, analyzing process parameters like speed or time, or validating training and software outcomes.

Client Testimonials

What Our Clients Say About Us?

We are trusted by thousands of clients belonging from technology, manufacturing, healthcare and various sectors

Our overall experience with Maxicert was satisfied. The audit and consulting part was handled carefully, we fulfilled our client requirement of ISO 27001 hassle free.

Kevin Santiago BDM – Clarks Outsourcing, PhilippinesTimely response and knowledge of ISO standards can be seen together in the team of Maxicert, we grow because of the service providers like Maxicert.

Samuel Christopher Quality Assurance Head – OEQA, NigeriaWe did Food safety certification with Maxicert, the service was extraordinary and their consultant had good experience of the subject.

Mr. Venkatesh Production Manager - Acacia Foods and Beverages, ZambiaWe engaged a consultant of Maxicert for our business certification, we now have a well-designed and organized department procedures and we rectify our errors through internal audits regularly.

Abdullah Al Rayes Managing Director – TCS, BahrainTechnical expertise by the team of Maxicert helped us achieving our ISO 13485 certificates, we now proudly say that we have achieved our target, all thanks to the team.

Nady Boustany CEO – LMG, IraqMaxiCert's approach to meet our needs proved instrumental in facilitating a seamless transition throughout the entire ISO certification process for us. Their training sessions are so much helpful.

Ms. Latifa Al Salem Investor portfolio – Ministry of Investment, Saudi ArabiaMaxicert is a one stop solution, we got trainings, documents, audit and certification at one place, they facilitated everything.

Ms. Mariam Chaggama VP – Fasthub, Tanzania

Their presence in Oman made us even better to accomplish our goal of achieving ISO certificates on time, we will definitely recommend their services.

Mr. Sailesh Mohanakrishnan Division Manager – Khimji Ramdas, Oman